Actemium Shanghai develops flexible ‘golden batch’ solution

FUCHS, a manufacturer of lubricants and greases, requires that the quality of the different batches reaches a ‘golden batch’ as close as possible.

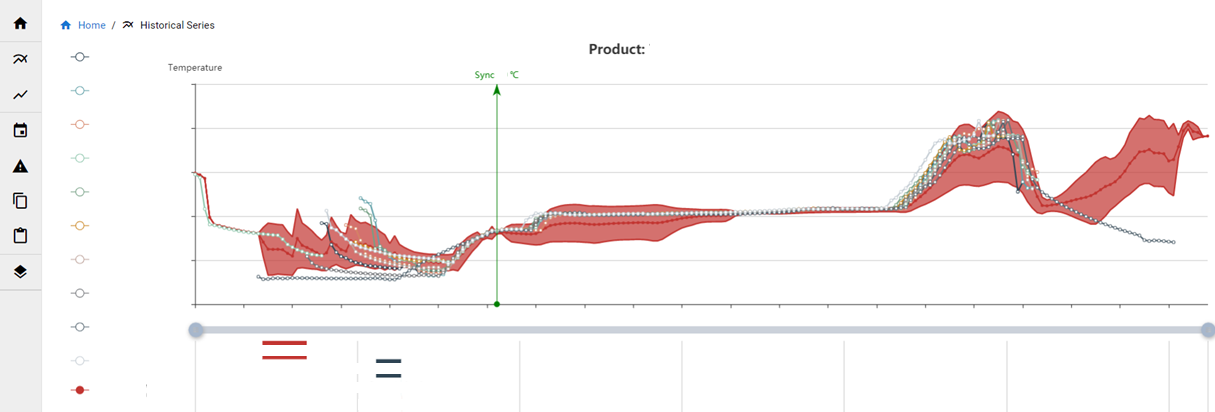

The golden batch is determined during the first production runs of the new product that is defined by capturing the trends of temperature and pressure.

The golden batch is determined during the first production runs of the new product that is defined by capturing the trends of temperature and pressure.

Then, the subsequent production runs of the same product are compared with the golden batch. If there is a need to make adjustments, Actemium’s golden batch solution alerts the operator to do so. Also, the system can be used to compare multiple batches and traceback quality issues. The golden batch solution is adaptable to fit any control system; it takes into account the different equipment sizes and types due to the fact that dissimilar equipment can impact the batch.

This solution fits into a bigger roadmap for FUCHS to digitize their plants worldwide.

For more information, please contact Davy Demeyer.