Merck Millipore Molsheim Designs the Next Generation of Its Tangential Flow Filtration Systems with Actemium

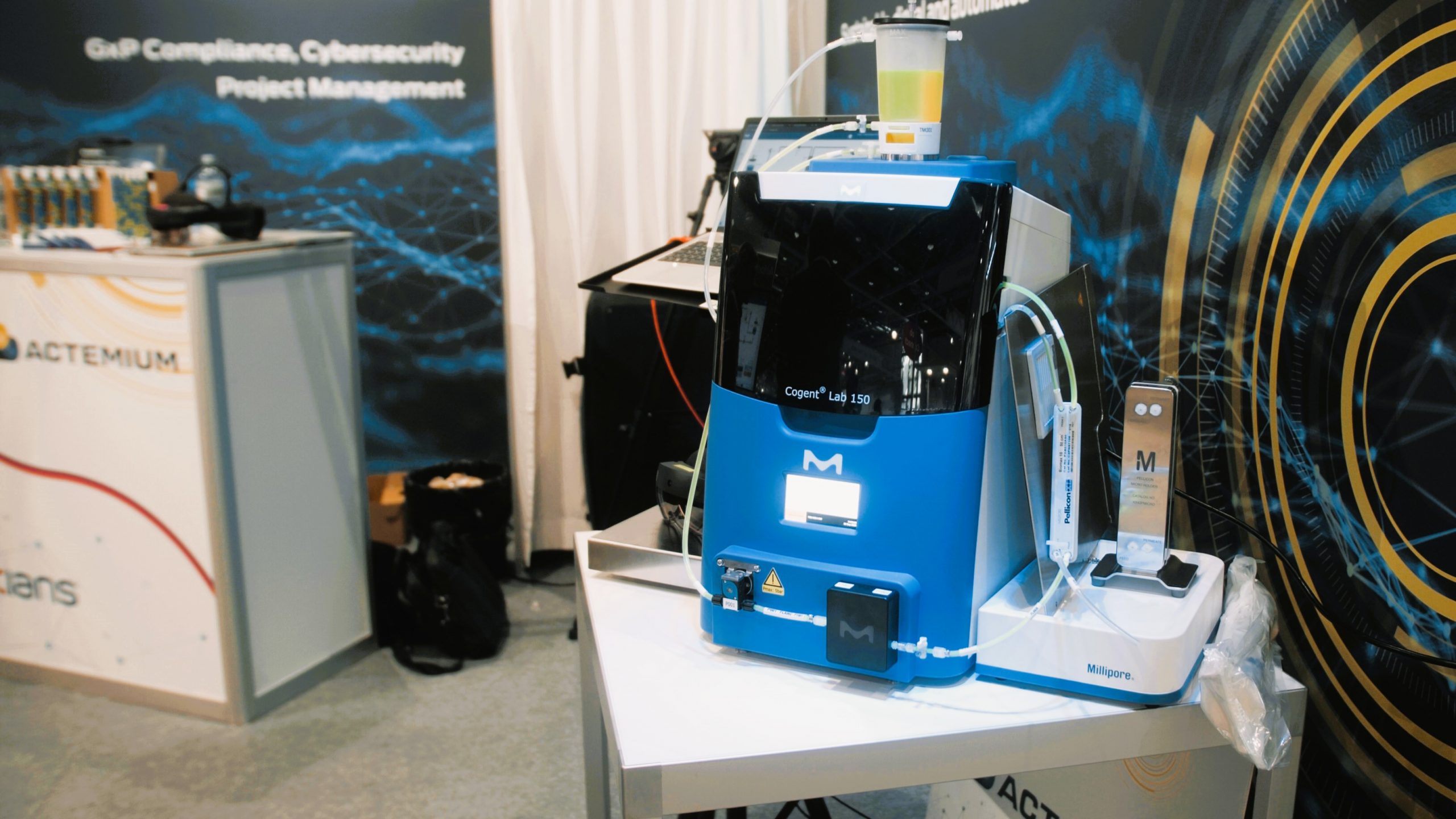

Located in Alsace, Merck Millipore Molsheim specializes in biomonitoring, water purification systems, single-use assemblies, and pharmaceutical filtration systems. As part of the latter activity, the pharmaceutical group decided in 2018 to renew its range of laboratory-scale tangential flow filtration (TFF) systems, branded Cogent®Lab. These systems enable the purification of liquids using tangential flow filtration at the “process development” scale.

“Merck Millipore wanted greater automation in the new generation of its filtration systems” explains Pierre Romann, Automation & Industrial IT Engineer at Actemium, who led the project in collaboration with three Actemium business units, Mulhouse, Basel, and Porrentruy.

“This Franco-Swiss collaboration was facilitated by the fact that Merck Millipore Molsheim has been a long-standing client of all three entities since 2002. Over the past twenty years, we’ve worked on various systems within Merck Millipore’s portfolio” adds Géraldine Lemeunier, Business Manager at Actemium.

Innovating and Meeting Market Needs by Merging IT and OT

The innovative requirements of the Cogent®Lab project provided Actemium’s team with the opportunity to combine automation and software development expertise across its network.

Creating a cutting-edge product based on web solutions required high coordination and strong commitment from everyone involved. We were able to converge IT and OT by applying tools and methods from the IT world to industrial automation — a forward-thinking approach that’s now gaining momentum

says Pierre Romann.

Actemium proposed a hardware architecture familiar enough to reassure us about platform capabilities, while incorporating extensive use of web technologies and Linux libraries to help control costs, offer robust features, and deliver a modern user experience

adds Nicolas Couzin, R&D Technical Project Manager at Merck Life Science.

Reduced Production Costs and Adaptable Software Platform

Another major challenge was integrating production-level functionalities (dashboard, recipes, reports) within the cost constraints of a laboratory system. Merck aimed to optimize its position in a market representing several hundred units per year. “By opting for in-house development, we not only reduced licensing costs but also gained greater freedom in the design,” notes Yann Seget, Software & Infrastructure Engineer.

Actemium also met the challenge of configurability by developing a single software platform adaptable across the entire product family — all while meeting a 2021 delivery deadline. “Over two years, we carried out a technical exploration phase with feasibility tests, followed by solution design, development, testing, and validation on physical prototypes. Finally, we supported the client through industrialization and product launch in 2022,” explains Jordan Mum, Project Engineer at Actemium.

Managing the Product Lifecycle

The project’s success also stems from its forward-thinking approach. Beyond incorporating IT technologies into an automation solution, Cogent®Lab provided the opportunity to develop a system update mechanism. “The software isn’t static. We’re constantly improving it. Recently, we added electronic signatures to production reports to ensure data integrity and authenticity. Clients can access new features by downloading a single file that enables them to perform updates themselves and thus manage the product lifecycle,” says Laurent Wehrlen, Software Engineer at Actemium.

A Co-Creation, Agile, and Incremental Approach

Another standout innovation lies in the project’s organizational model — a collaborative approach with the client. “From the outset, we adopted an agile co-creation methodology,” says the Business Manager. “With each iteration, we refined goals while staying mindful of required efforts. This incremental and collaborative work was completed within the originally planned costs and timelines thanks to the commitment of both Merck and Actemium.”

Merck’s Nicolas Couzin agrees:

Actemium adapted its team to support solution development, despite our small project team. We gained access to technologies we hadn’t mastered before. Progress updates were shared transparently by both sides. Our co-development teams complemented each other very well.

Following the launch of the new Cogent®Lab range, Actemium also developed a virtual marketing portfolio for Merck’s sales team — accessible via a web app and iPad — to showcase its Bioprocessing Systems product line. “This specific project involved other skill sets within the Actemium network, particularly in 3D and augmented reality, to present the products in context,” adds Pierre Romann.