Optimization Starts at Home: Actemium Units Work Together to Streamline Schematics Versioning

Actemium Netherlands helps its clients become more efficient by designing, building, optimizing and maintaining industrial processes in a wide variety of industries — from food to green energy, to tire manufacturing. The company is proud of its reputation for agility, flexibility, and innovation.

Just as it is constantly looking for innovative solutions and services for its customers, it seeks the same for itself. When optimizing internally, the work for clients improves.

Applying expertise to streamline a time-consuming task

About two and a half years ago, Robert Gieben, Business Unit General Manager at Actemium in Veghel, decided the time had come to automate one of the most time-consuming activities his engineering colleagues face: annotating and updating schematics.

Schematics — the detailed blueprints for engineering projects that show how every element fits and what it does — have to be updated constantly as new ideas, improvements and corrections are planned. This painstaking process involves printing out sheets of paper, marking them up by hand using different coloured pens, and then transposing the changes into Excel spreadsheets.

Our colleagues at Actemium Energy AI in Sweden have some serious software development skills. So we asked if they could put some of their software engineers to work on automating the schematics workflow.

Mr. Gieben said.

Calling in the Actemium AI experts

Marie Kurtin, Business Unit Manager at Actemium Energy AI, saw the potential and agreed to help form a group led by Léon Löwered, Head of Innovation and Technology at Energy AI, to create the software service eventually dubbed SCHEMIRA. Actemium Energy AI, based in Gothenburg, Sweden is a team of skilled data scientists with strong R&D backgrounds, designing and developing AI solutions that help customers optimize their processes.

From the outset, the collaboration between Actemium in Veghel and Actemium Energy AI was close and hands-on, with regular check-ins to ensure the solution matched how engineers actually work with schematics. Rather than starting with a fixed commercial strategy, the solution and business model evolved organically as it became clear that manual schematic handling was a widespread pain point.

This led to a pay-per-use model, lowering the barrier to entry while allowing adoption to scale naturally. Beyond the technical outcome, the collaboration itself has been highly positive, with clear improvements to engineers’ daily work. New projects are already underway in Veghel and Gothenburg, highlighting both the value of the solution and the strength of the partnership.

A working group was established early on to define the project scope, focusing on:

- Version comparisons

- Change detection and reporting

- Historical tracking of modifications

It has since evolved to include more functions and areas of schematics.

Training machines and people

Initially, the software will be offered within Actemium and the wider VINCI Energies group as a pay-as-you-go SaaS solution. While SCHEMIRA shows strong potential in the external market, the initial focus is on internal deployment, where the need is already substantial. Expansion beyond the group may be considered at a later stage.

The rollout involves a dual learning curve, for both users and the system. Training the software for each type of schematic takes time and resources — as does creating customer-specific secure cloud environments.

Colleagues as super users and “customers”

It took 18 months from the inception of the project to get a minimum viable product (MVP) that was tested by Actemium “super users” who ran it through its paces and suggested many improvements. As Léon Löwered, Head of Innovation and Technology at Actemium Energy AI, explains:

We encouraged the team in Veghel to really challenge the solution and even try to crash the software. That helped us identify issues early and improve the tool much faster.

While it is difficult to quantify the time the system will eventually save, Gieben noted that it takes “hours” to manually transpose every change in a schematic to an Excel database. With SCHEMIRA, this will be reduced to minutes, freeing up engineers to tackle more cerebral tasks. He added that errors and omissions would also be avoided with the automation of this task.

AI is making a difference across the Actemium network

Artificial Intelligence is not just a buzzword at Actemium. More than a hundred AI projects are underway across the Actemium network, harnessing advanced models to predict, optimize, and detect with unmatched precision.

One-third of these initiatives are in development, another third is already delivering tangible value to clients, and ten standout solutions — including SCHEMIRA — integrate AI to empower our engineers and industrial operators, making their work smarter and more efficient.

These tools are designed to be shared across the entire network, underscoring Actemium’s leadership in shaping the future of industry.

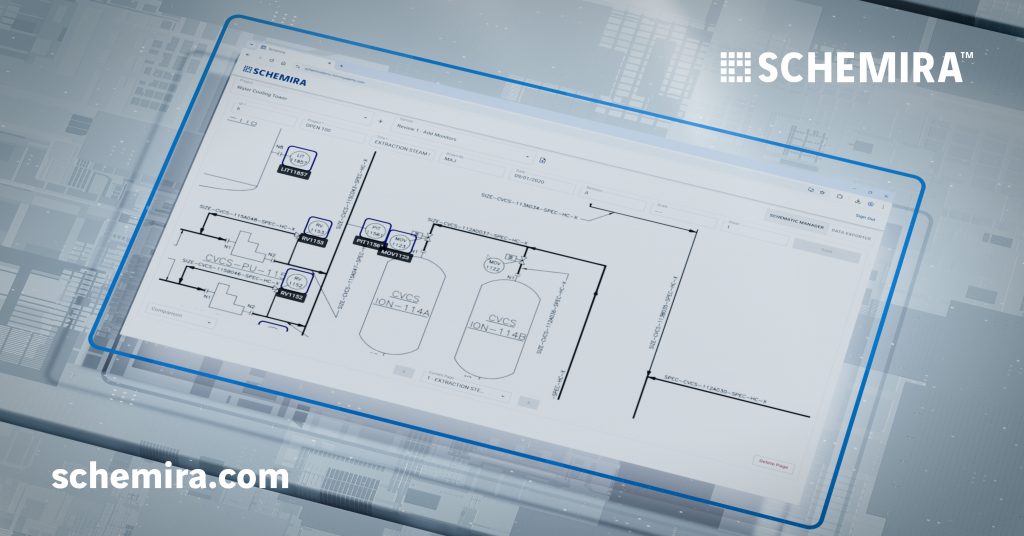

Rewarding intelligence that is easy to use

Gieben said that currently about 25-30 percent of the potential SCHEMIRA “customers” in his business unit were using the system. “At this point in time, it doesn’t have hundreds of functionalities, though it is an intelligent tool with an easy-to-use interface,” Gieben said. “I think it is easy to organically flow through the system.”

Improvements, deployments, and implementation continue apace, and Gieben said that he expects the usage rate to rise to as much as 90 percent by mid-February 2026.

Pieter van Rees, an Actemium engineer, described how a client sought a new quote based on a fourth schematics revision.

SCHEMIRA allowed me to scan 20 documents within half an hour and come up with a new price within the hour, saving a lot of time. Our joint vision really paid off today.

“We’re a group of automation specialists that set out to automate one of our own processes,” Gieben said. “And it looks like it’s a success.”