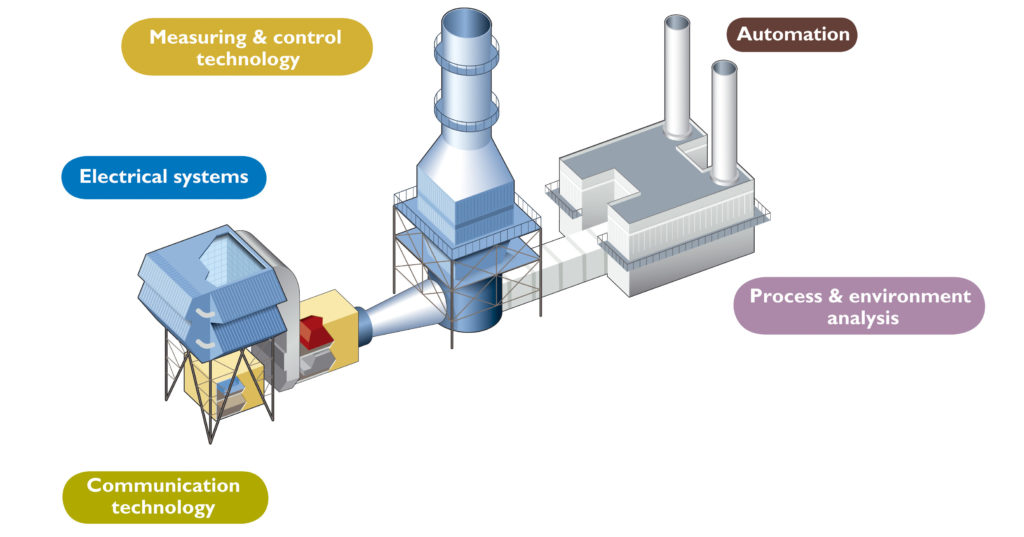

Solutions / Expertise

For energy generation facilities (including hydro-electric power stations), Actemium offers instrumentation, automation and control system solutions and work on HV/LV facilities.

ELECTRICAL ENGINEERING

- High voltage switchboards (up to 20 kV)

- Medium voltage switchboards (6-20 kV)

- Low voltage switchboards (400V/690V)

- Transformers

- Frequency converters

- Stand-by units / UPS-units

- Lighting systems

- Wiring

EMISSION CONTROL

- Complete emission monitoring systems according to law

- Integration of other measuring components via I/O-cards

- Self-explaining, continuous operation

- Calibration without test gases

- Remote control and operation via PC-network

- PC-support of periodical emission report

MEASURING AND CONTROL TECHNOLOGY

- Field devices

- Software & hardware controller

- Field bus

- Small piping

- Air distribution boxes

- Transmitters

- Fire alarm systems

- Video technology

AUTOMATION

Cost efficiency and reliability: custom designed solutions based on industrial process control (PCS7, ABB Freelance 2000, etc.)

- PCS7 based flexible library MFL

- Centralised or decentralised configuration

- Integration of standard or fail safe periphery

- Simple or complex diagnostic function

- Compliance with current power

- plants norms (KKS, VGB 170C, etc.)